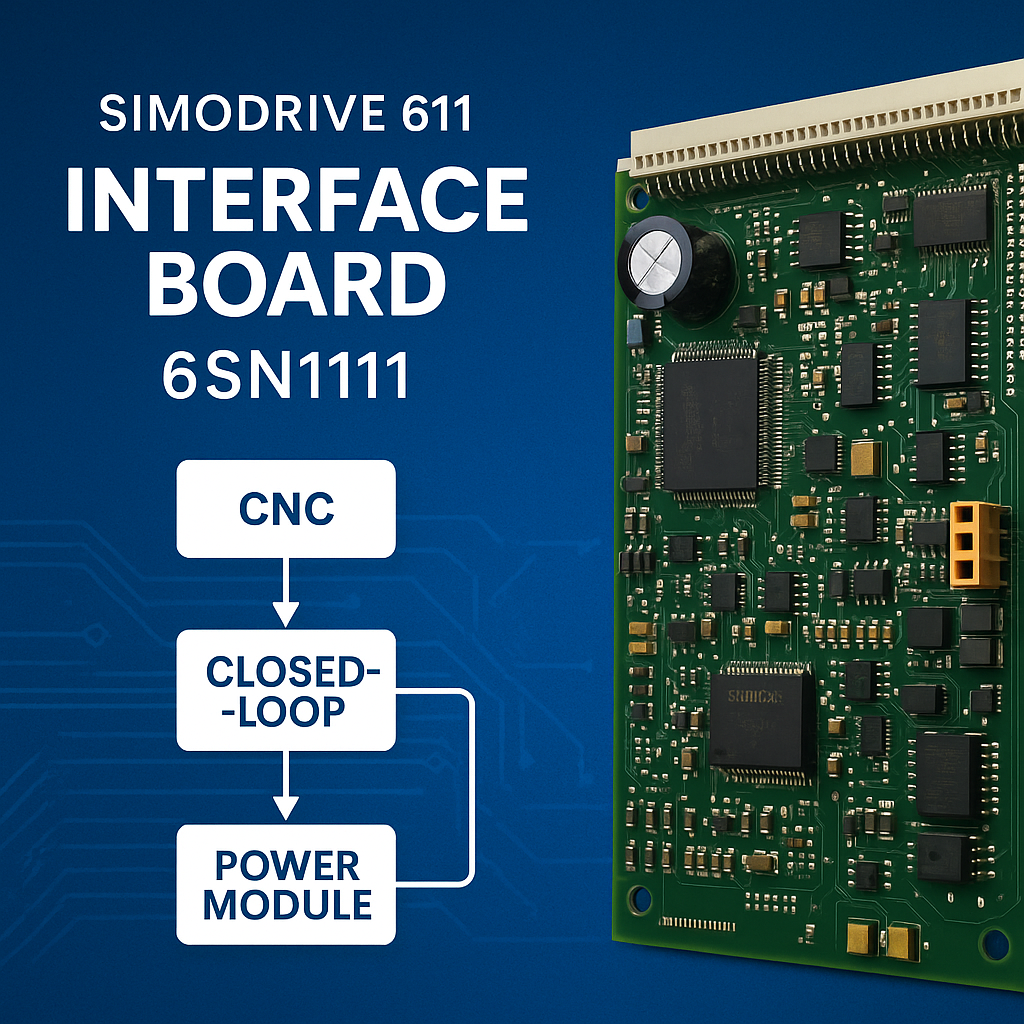

⚙️ The 6SN1111 Root – SIMODRIVE Interface Boards

The 6SN1111 boards belong to the Interface / Communication Board category within the SIMODRIVE system.

This family includes several models, differentiated by:

-

the type of signal handled

-

the number of channels

-

encoder feedback connections

-

compatibility with specific versions of modules 6SN1118, 6SN1123/1124/1125

-

additional functions (diagnostics, synchronization, machine expansions)

Main Functions of the 6SN1111 Series

🔹 Encoder / Resolver Interface

Provides the link between the motor and the control module, managing position feedback.

🔹 Signal Conversion and Filtering

Adapts input/output signals to Siemens standards.

🔹 Axis Synchronization

Required in multi-axis configurations or systems with synchronized spindles.

🔹 Siemens Proprietary Communication Bus

Manages high-speed communication between SIMODRIVE modules.

🔹 Support for Advanced CNC Configurations

Used in SINUMERIK 810D / 840D / 840Di machine tools.

🔗 Complete 6SN1111 Range – E-Repair Catalogue

https://www.e-repair.com/products-catalogue/simodrive/?q=6sn1111

🏭 Typical Applications of 6SN1111 Interface Boards

These interface boards are used in:

-

Multi-axis CNC machining centers

-

CNC turning machines

-

Milling and grinding machines

-

Laser and waterjet cutting systems

-

Robotic production lines

-

Pick-and-place systems

-

High-precision industrial automation

They are critical components: a faulty board can stop an entire axis or spindle.

🔧 E-Repair Services for Siemens 6SN1111 Boards

E-Repair is an Approved Siemens Partner – Industry Services, the only authorized European laboratory for the repair and refurbishment of the SIMODRIVE 611 range.

For 6SN1111 boards, we offer:

🧩 Siemens-Certified Repair

Diagnostics performed on original SINUMERIK test benches with full simulation.

🔁 “Zero-Hour” Refurbishment

Replacement of worn components, circuit restoration, thermal and electrical testing.

⚡ Advance Replacement (Refurbished or New Unit)

Minimizes machine downtime.

🧠 Backup and Signal Verification

Testing of encoder feedback, resolver channels, and communication interfaces.

🌐 On-Site and Remote Support (MAAS)

Certified technical assistance for troubleshooting and axis configuration.

🔒 E-Repair Standard Warranty: 12 months in accordance with Siemens standards

Extension available up to 24 months for selected products, upon request.

🌱 Quality, Sustainability and Security Standards

All E-Repair processes comply with:

-

BS 8001:2017 – Circular Economy

-

AFNOR XP X30-901:2018 – Circular Models

-

ISO 14064-1 – Carbon Footprint

-

ISO 27001 – Industrial Cybersecurity

6SN1111: Operational Continuity and Certified Refurbishment

SIMODRIVE 611 6SN1111 Interface Boards are essential for proper communication and synchronization of machine axes.

Thanks to their modular structure and high reliability, they remain a cornerstone of SINUMERIK systems still operating throughout Europe.

As the only Approved Siemens Partner, E-Repair ensures the highest quality in refurbishing these components, extending machine life and guaranteeing production continuity—even in older but still strategic systems.

🟢 Article based on technical content developed for E-Repair official channels.

Español (España)

Español (España)  Deutsch (Deutschland)

Deutsch (Deutschland)  Français

Français  Italiano

Italiano