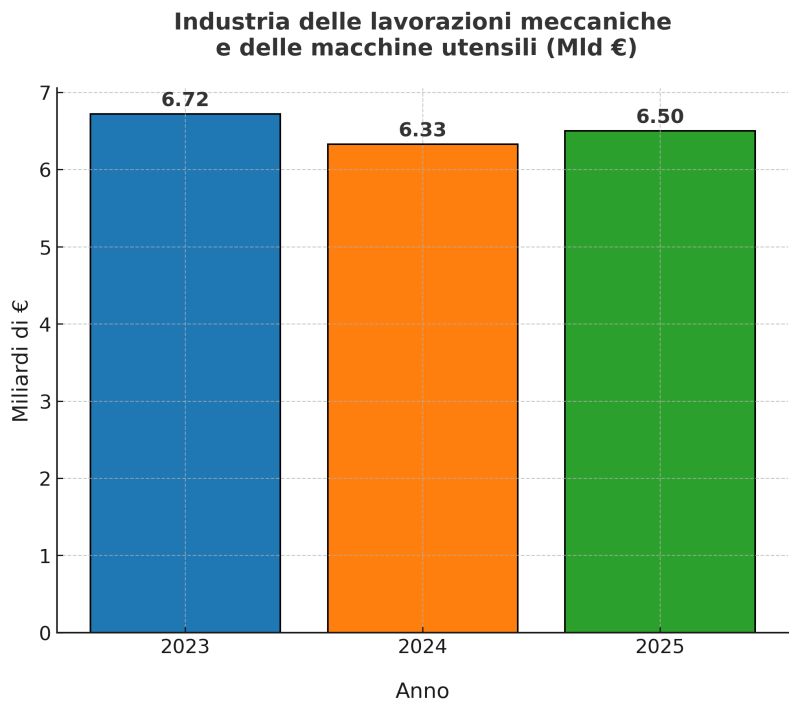

After a challenging 2024, the Italian precision mechanics and machine tool industry looks to 2025 with cautious optimism.

According to UCIMU data, production is expected to grow again, reaching an estimated €6.5 billion, up from €6.3 billion in 2024.

This recovery is mainly driven by exports, which continue to represent the key engine of Italian competitiveness, along with a gradual rebound in domestic investments.

🔧 The Technological Drivers of Change

Global demand is pushing the sector toward an increasingly technological evolution. Among the main trends reshaping the production landscape are:

-

Multiaxis machining to reduce setup times and production costs.

-

Sensors and predictive maintenance to improve the reliability of machine tools.

-

Superalloys and advanced materials, requiring ultra-high-precision machining processes.

-

Digital simulations and Digital Twin technologies, enabling project validation before actual production.

A mix of innovation and know-how that strengthens Italy’s reputation as an international center of manufacturing excellence.

💡 E-Repair’s Commitment to Production Continuity

In this context of technological transformation, E-Repair supports the manufacturing and precision mechanics supply chain through an advanced servitization model – MAAS (Maintenance as a Service).

With its Siemens-certified technical laboratory and expertise in industrial electronic regeneration, E-Repair provides:

-

Predictive and corrective maintenance for drives, CNCs, inverters, and controllers;

-

“Zero-hour” regeneration and technological washing of electronic components;

-

Certified backups and industrial cybersecurity (ISO 27001);

-

Up to 24-month warranty, with processes compliant with BS 8001:2017 and ISO 14064-1 (Scope 3) standards.

A complete range of services designed to ensure production continuity, sustainability, and international competitiveness.

Español (España)

Español (España)  Deutsch (Deutschland)

Deutsch (Deutschland)  Français

Français  Italiano

Italiano