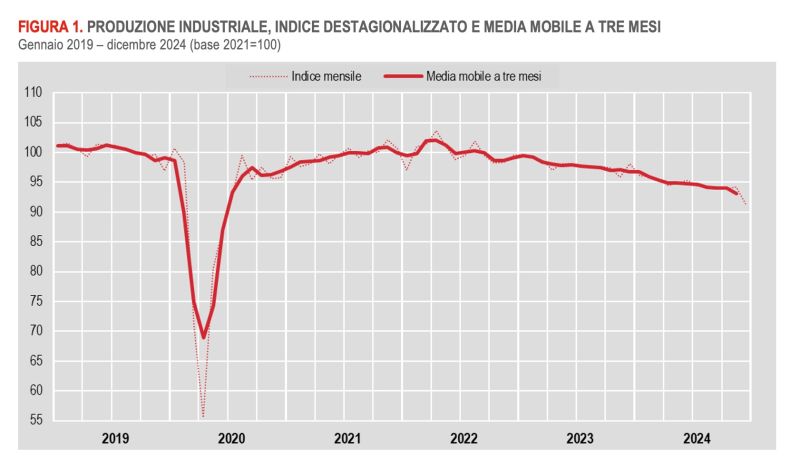

🏭 A challenging year for almost all sectors

The only segment showing slight growth is the food, beverage, and tobacco industries, which recorded a +1.8% annual increase.

All other manufacturing sectors experienced significant declines, with double-digit drops in the manufacturing of transport equipment (automotive sector) and the textile, clothing, leather, and accessories industries (fashion sector).

⚙️ A context that demands resilience and innovation

This scenario highlights the urgency for manufacturing companies to strengthen production resilience and invest in advanced maintenance technologies, digitalization, and regeneration services in a circular economy perspective.

Operational continuity has become a strategic priority to face unstable economic cycles and reduce costs arising from plant downtime or inefficiencies.

🔧 The role of E-Repair in production continuity

In this context, E-Repair, an Approved Partner Siemens and a leader in industrial electronic maintenance, supports companies every day in maintaining high plant efficiency through:

-

repair, regeneration, and technical assistance services (on-site and remote),

-

certified machine data backups and industrial cybersecurity systems,

-

advanced predictive maintenance and servitization solutions (MAAS – Maintenance as a Service),

-

an integrated approach to sustainability, in line with ISO 14064-1, BS 8001:2017, and AFNOR XP X30-901 standards.

Thanks to a model based on production continuity, innovation, and sustainability, E-Repair helps companies overcome periods of industrial contraction, turning them into opportunities for improvement.

💬 We truly hope that 2025 marks a real turning point — the recovery of the manufacturing sector also depends on strategic choices focused on advanced maintenance and sustainable transition.

🟢 Article based on content published on E-Repair’s official social media channels.

Español (España)

Español (España)  Deutsch (Deutschland)

Deutsch (Deutschland)  Français

Français  Italiano

Italiano