⚙️ Production continuity: the real competitive lever for 2025–2027

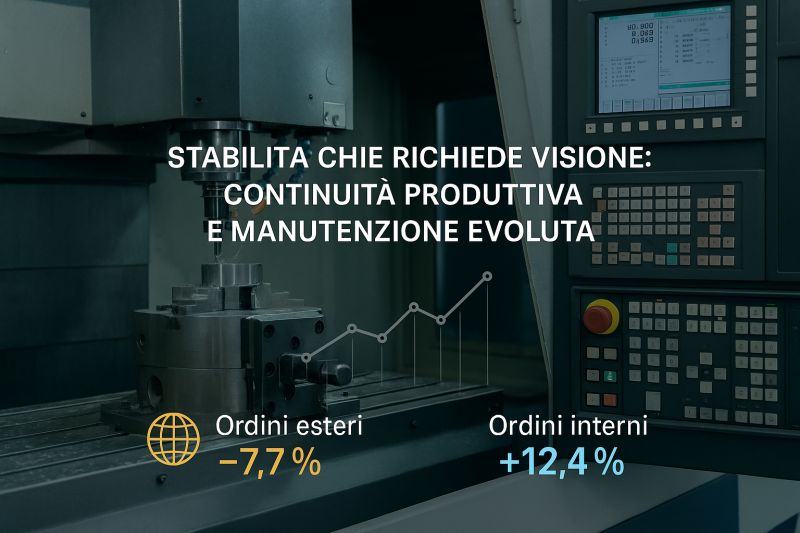

In a context of volatile demand and unstable global supplies, competitiveness is no longer driven solely by price or output.

It is driven by production continuity.

Investing today in:

-

advanced maintenance

-

certified electronic regeneration

-

machine data backup and protection

-

predictive and improvement-focused diagnostics

-

MAAS – Maintenance as a Service

means securing industrial assets, reducing unplanned downtime, and making the company less dependent on extra-EU supply chains, which are often exposed to delays, uncertainty, and limited quality transparency.

🔌 Electronic regeneration as a response to supply chain fragility

Companies are increasingly realizing that relying on used, untested components sourced from unofficial suppliers introduces significant risks:

-

recurring failures

-

software incompatibility

-

lack of traceability

-

long lead times for replacements or returns

-

loss of production continuity

Certified regeneration of Siemens electronic components — with full testing, firmware updates, and up to 24 months of warranty — provides a concrete response to these vulnerabilities.

🌱 E-Repair and the Siemens Industry Services model

As an Approved Partner Siemens – Industry Services, E-Repair supports Italian manufacturing companies in achieving:

-

more resilient plants

-

more efficient processes

-

more transparent and controllable supply chains

-

a more sustainable production model, in line with European goals for re-industrialization and Scope 3 emission reduction

Zero-hour regeneration, on-site assistance, original SINUMERIK test benches, and advanced diagnostic procedures enable truly advanced maintenance that extends equipment life and reduces technological waste.

🏭 Towards a more autonomous, digital, and sustainable manufacturing ecosystem

The 2026–2027 period will be decisive:

-

new incentives for re-industrialization

-

updates to Transizione 5.0 programs

-

increased focus on supply chain security

-

stricter ESG requirements

-

accelerating digitalization of production processes

Companies that invest in production continuity and improvement-focused maintenance will be ready to compete in a market that demands stability, efficiency, and environmental responsibility.

🟢 Article based on content published on E-Repair’s official social media channels.

Español (España)

Español (España)  Deutsch (Deutschland)

Deutsch (Deutschland)  Français

Français  Italiano

Italiano